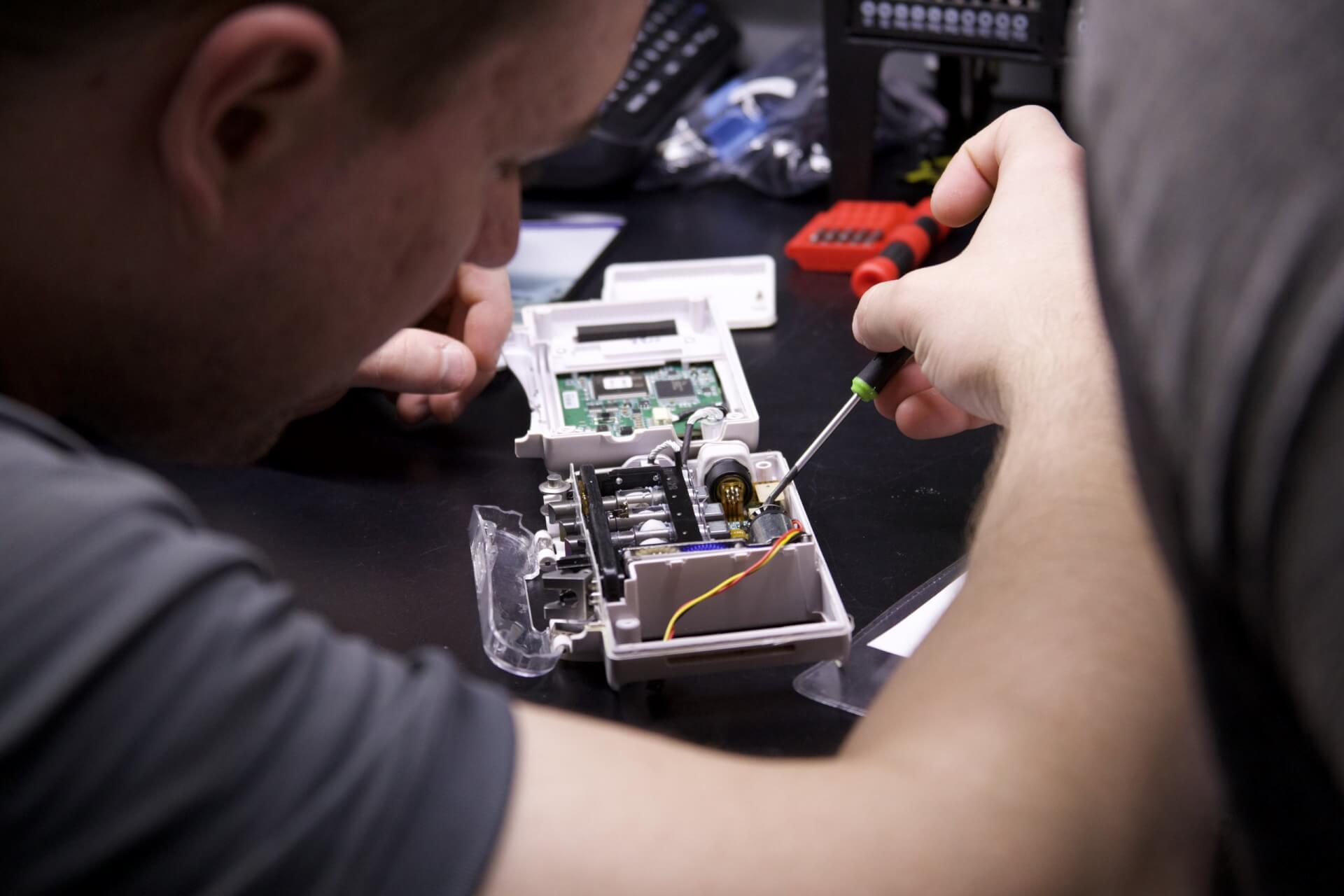

The infusion pump is one of the best examples regarding the importance of consistent maintenance. With devices that have direct access to bloodstream infusion, the upkeep and calibration of the unit is paramount.

Each infusion pump that is put through ReNew Biomedical’s Preventative Maintenance is calibrated to factory-standard condition and returned to practice as fast as possible. Josh and JL, our infusion pump experts, explain more about the PM and repair process for pumps below.

“Each infusion pump has a unique repair and preventative maintenance path, with special software to diagnose and calibrate the device or specific kits tailored to repair these devices. Many pieces go together when going through the preventative maintenance process, and each process holds something a little different based on your type of pump,” Josh explains.

“For example, Baxter hasn’t released specialized test software for the Sigma series of infusion pumps, but they do provide a test kit for their infusion pumps,” he added. “Eitan’s Sapphire series holds a personalized test kit and software; Alaris has both test programs and equipment.”

“After we have the appropriate tools, we carefully analyze each facet of the equipment,” he said. “Everything from a cursory overlook to detailed examinations of the air accuracy, flow, and occlusion on both sides of the devices, including checking the power cable.”

“ReNew meets the needs of your infusion pumps. We have a couple of layers of service for your devices,” JL said. “We have two layers of service regarding what we can provide. We have our first level of repair, which constitutes our preventative maintenance, as well as batteries and light cosmetic damages (springs, covers and clips).”

“Our second level of care is more encompassing and includes more complicated repairs for the device. Our trained and experienced experts deal with full restorations and other maintenance,” he added.

“After each repair has finished, the device takes one final test. Biomedical technicians for a long time have called it the ‘Answer’ test. This diagnostic technology has been adapted into an all-encompassing program called 1QA,” JL said.

1QA is a cloud-based diagnostic software for various medical devices; these devices test for a set of parameters they must meet to be considered repaired by ReNew Biomedical’s standards. Once the device repair is complete, our technicians send reports to the customer and the device for shipping.”

ReNew Biomedical’s premiere service technicians have proven their place in the global market. These processes are carefully constructed to produce clean and efficient results for every device.

ReNew Biomedical has captured manufacturers’ attention with its premium equipment service. For infusion pumps, Eitan Medical has authorized ReNew as an authorized service center for Level I service and Level II service of the Sapphire series of infusion pumps.

Have a question about your device or our service? Call at 866-955-3039 or email service@renewbiomedical.com to speak directly with a service coordinator and find a solution that’s right for you!